FLEW Solutions

FLEW Solutions provide a range of advanced manufacturing solutions including laser welding, advanced materials production, smelting services and manufacturing aids.

Overview

Promising outputs have been realised from the collaborations between ACEMS and FLEW Solutions, including technology for commercialisation via a newly incorporated affiliated company of FLEW Solutions (CloudForge). To increase the technology readiness and commercial applications of this technology, a new ICSS application was granted to co-fund further R&D, and a new paid APR Intern Industry internship project negotiated for ACEMS QUT PhD student Ethan Goan (with proposed Innovative Manufacturing CRC support). Research planning and meetings developed a new project idea, applying cryptography to 3DP contexts, which aims to involve ACEMS QUT and NSW collaborators in 2021, and to engage further research talent. A longer term goal of the partners is to apply for CRC-P or Linkage funding in the future, building on the success of the aforementioned collaborations.

Collaboration Highlights in 2020

| Collaboration | Description of Project (current, completed, or proposed) |

|---|---|

Detection of 3D print job faults using computer vision and machine learning (project completed) |

|

ICSS project “Detecting 3D Printing Faults using Machine Learning” (R&D to increase TRL of solution, including scalability, generalisability, readiness for market, and commercialisation potential) |

|

|

APR Intern Internship for Ethan Goan

ACEMS PhD student Ethan Goan (left) with Machine Learning Specialist at FLEW Solutions Australia, Samuel Fogarty (right) |

|

Proposed Cryptography Research Project |

|

Proposed CRC-P / ARC Linkage |

|

Engagement Highlights

ACEMS COVID-19 Workshop

FLEW Solutions’ CEO Michael Larkins attended ACEMS COVID-19 research workshop and delivered a presentation “Emergency Crowdsourcing for COVID-19 PPE”.

FLEW Solutions’ normal business includes 3Dprinting medical equipment, such as protective articles for radiotherapy.

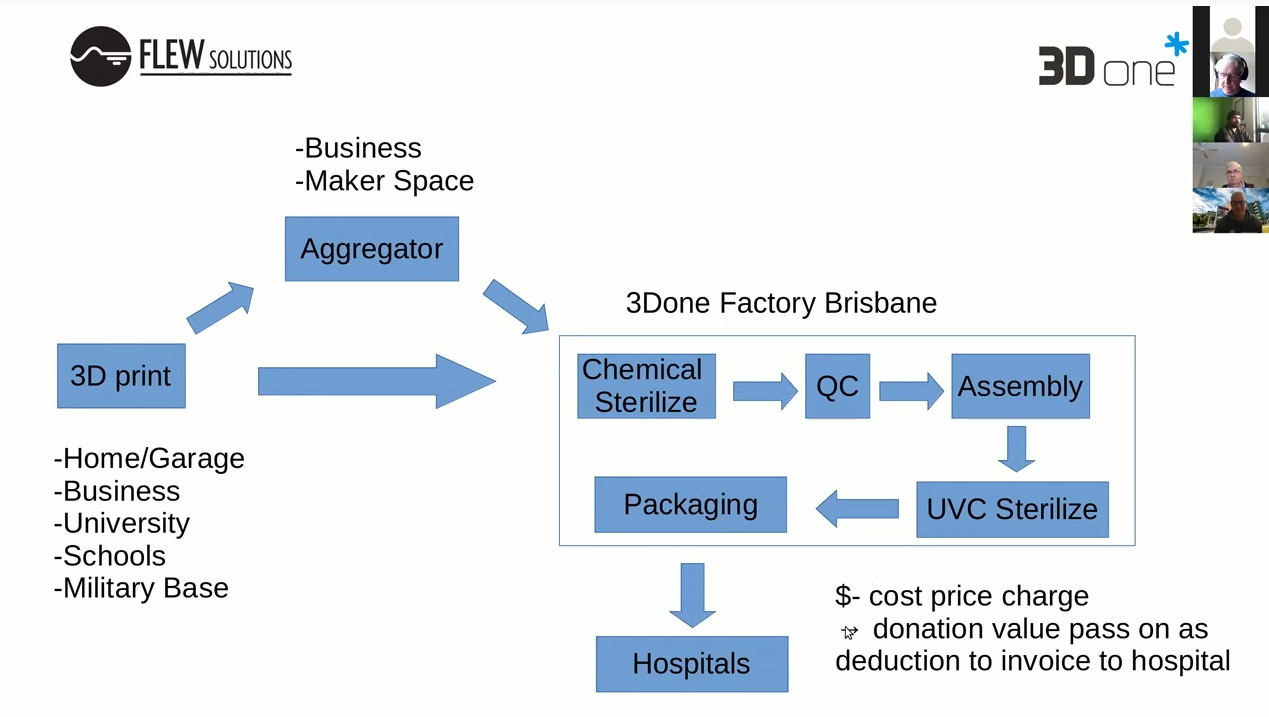

In response to shortages of medical supplies during COVID-19, FLEW Solutions decided to use its capabilities and infrastructure to support emergency efforts to ensure hospital supplies of PPE.

They harnessed distributed 3D printing capabilities, by using crowdsourcing and sharing designs, to increase supply capacity. With its TGA approval, it managed quality control and distribution to hospitals in Australia (then overseas).

Michael also discussed the new machine learning technology being developed by FLEW with ACEMS, for the reduction of printing failures. In this context, it could significantly reduce rejection rates by a factor of 10 (from 30% to 3%), thus helping to ensure critical supplies and limit resource wastage.

Commercialisation Highlights

Newly incorporated affiliated company of FLEW Solutions (CloudForge) aims to commercialise the technology which is the subject of the current research and development project using machine learning to detect 3D printing faults. See the Impact the Case Study for more details.

The expected impact from commercialisation, beyond benefits to FLEW Solutions/CloudForge, includes environmental (efficient use of resources, reduced emissions, use of recycled materials), health (fewer delays to patient treatments requiring 3D printed products), and economic benefits (improved supply chains, efficiency, lower costs).

Plans for 2021

2021 is expected to be a strong year for the collaboration, with the ICSS and Internship, plus we hope to progress other planned projects detailed above.