Queensland Department of Agriculture and Fisheries (QDAF)

The Queensland Department of Agriculture and Fisheries (QDAF) works to achieve a productive and profitable agriculture, fisheries and forestry sector, by promoting sustainability and innovation, and providing leadership for the sector which adds value to the economy and community.

QDAF serves to provide an efficient, innovative and resilient agricultural, fisheries and forestry sectors.

ACEMS researchers collaborated with QDAF to economically benefit the forestry industry. The forestry industry makes a significant contribution to the Queensland economy, with around 9,000 direct employees generating an estimated $3.8 billion in turnover in 2020.

QDAF’s Forest Product Innovation team is engaged in important R&D to support Queensland’s forest and timber industry. This work, on behalf of QDAF and its industry clients, includes investigating and improving solid wood processing, timber drying, timber quality, engineered wood products, adhesive systems, and timber durability and treatments, as well as the use of non-destructive tools to evaluate timber material products.

Chandan Kumar

QDAF’s forest product innovation team provides R&D support to the state’s important forestry industry.

Through ACEMS’ contribution to QDAF’s collaborative research projects, we have been able to harness sophisticated mathematical modelling to deliver a positive economic impact for the forestry industry. Our projects have delivered better understanding, predictions, and improvements in the wood drying process; and improved understanding of the performance and value of logs and sawn timber products.”

– Chandan Kumar, Senior Scientist & Engineer, QDAF

Project: "Impact of continuous drying on key production and performance criteria of engineered wood structural elements"

In 2020, ACEMS researchers collaborated with QDAF’s forest product innovation team on the above titled QDAF-led ARC Future Timber Hub project with industry partners Hyne Timber and Lendlease. This project involved ACEMS Research Fellow Steven Psaltis and CI Ian Turner working on mathematical modelling of timber drying. This project is currently completing a large-scale trial, led by QDAF’s Chandan Kumar, to investigate the impact of continuous drying kiln (CDK) technology on various quality parameters of Australian Southern Pine timber.

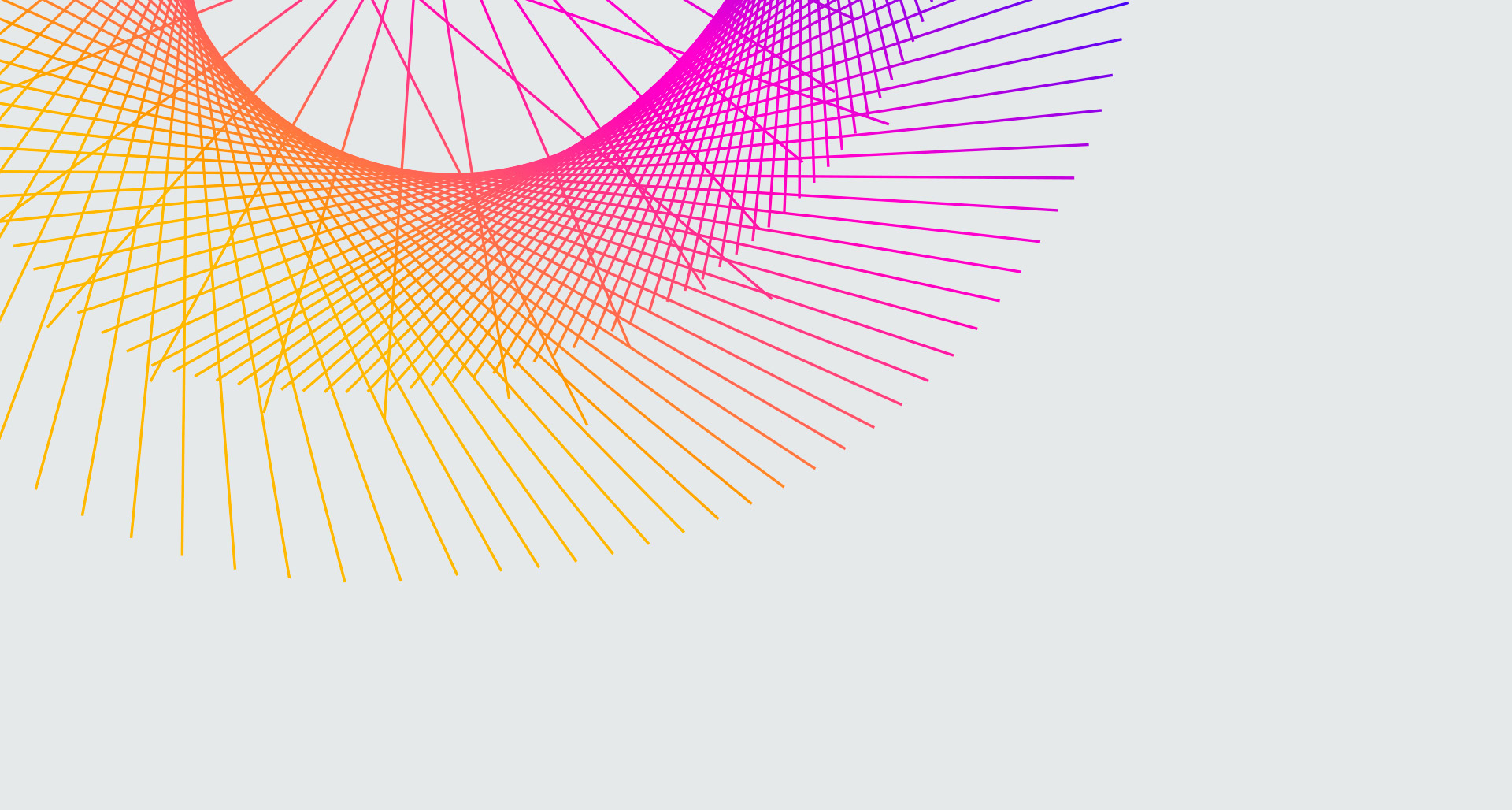

Drying experiments are trial-and-error based, expensive, time consuming and present difficulties with respect to measuring and understanding degradation and internal stress during drying and how drying schedule impacts product quality, time and energy. To help address these issues, ACEMS provided research expertise in mathematical modelling which helped to:

- Develop a comprehensive 3D multiphase timber drying model

- Investigate internal temperature and moisture distribution

- Develop a suitable drying schedule

As a result of the ACEMS research, QDAF and project partners are able to use a heat and mass transfer model to internally visualise, investigate, and predict timber moisture content and distribution at different drying times, and thereby improve the drying process – to increase efficiency and reduce product degradation.

This project was featured by the ARC Future Timber Hub as part of its February 2021 Research Showcase.

Project: “Innovative resource characterisation project: Virtual Log & Forest Value Prediction

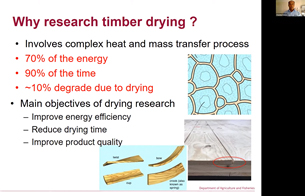

ACEMS CI Ian Turner, Research Fellow Steven Psaltis, and Associate Investigator Troy Farrell have also continued earlier research with QDAF related to virtual log models for forest value prediction, namely, predicting the performance and value of sawn timber products, based on stiffness, or modulus of elasticity (MOE), value grades.

This work has resulted in the development of 2D and 3D models which can predict MOE of logs and boards that can be obtained from a forest, including the property of a tree or log at any height or radius, with improved accuracy and reduced error. The multi-disciplinary team has developed a novel non-destructive method to predict MOE of logs and boards using measurements from cores extracted from discs. With this method, it’s possible to use a single core from tree breast height to predict MOE of logs, allowing early grading and sorting of logs for optimal use and processing, generating improved financial return and reduction of wood wastage.

The benefits to industry include improving informed decision-making at mills, reducing the risk of producing low-value sawn boards and guidance to forestry growers identifying low/high quality plots.

This was a large-scale collaborative project funded by Forest & Wood Products Australia, QDAF, HQPlantations Pty Ltd., Hyne and Son Pty Ltd., Forest Corporation New South Wales and led by David Lee from the University of the Sunshine Coast.

Supervised Research Student

Ian Turner and Steven Psaltis’ honours student Patrick Grant completed his thesis in 2020, on the topic “Efficient MATLAB Code Implementations of Unstructured Mesh Finite Volume Solvers”. His work was related to coding implementation for the 2D model for QDAF.

In 2021, Patrick will undertake a PhD with ACEMS on a topic related to the QDAF-ACEMS collaborative work aiming to develop a comprehensive mathematical model to advance understanding of the impact of moisture migration on the structural integrity of laminated timber products, using QDAF experimental data for model validation. His research also seeks to identify mechanisms that can prevent long-term damage to building structures when exposed to harsh Australian climate conditions, thereby benefiting the timber and construction industry and property owners.